Why the Holiday Season Stresses Global Supply Chains

As the holiday shopping season ramps up, supply chains face a perfect storm: rising demand, strained transportation networks, limited labor, and sharp increases in returns.

For logistics managers and high-value cargo shippers, this period introduces elevated risks:

- Delays and missed deliveries

- Misrouted or lost shipments

- Overstocking or stockouts

- Reverse logistics bottlenecks

Key Supply Chain Pressures During the Holidays

1. Increased Demand Across the Board

Consumer demand spikes dramatically between November and January. According to the National Retail Federation, U.S. holiday sales in 2024 surpassed $960 billion, putting massive pressure on production, warehousing, and transport infrastructure.

2. Shipping Challenges and Carrier Congestion

Parcel volumes rise by 20–30% during peak months, according to Pitney Bowes. This surge leads to:

- Overloaded carriers and couriers

- Compressed shipping windows

- Higher transportation costs

High-value or sensitive shipments are especially vulnerable when carrier networks are overwhelmed.

3. Inventory Management Strains

Retailers must strike a delicate balance:

- Under-forecasting leads to stockouts and lost revenue

- Over-ordering leads to warehousing issues and unsold inventory

This requires tight coordination between forecasting systems, fulfillment operations, and real-time inventory tracking.

4. Operational Strain on Warehouses and Teams

With warehouses running near full capacity, logistics providers often depend on seasonal labor. This introduces new variables:

- Less experienced workers

- Inconsistent handling practices

- Increased risk of damage or misplacement

5. Post-Holiday Return Surge

The National Retail Federation reports that 17% of holiday purchases are returned. This creates a massive reverse logistics challenge:

- Increased transportation and handling costs

- Delays in resale or restocking

- Cash flow impact from tied-up inventory

How Real-Time Tracking Can Protect High-Value Shipments

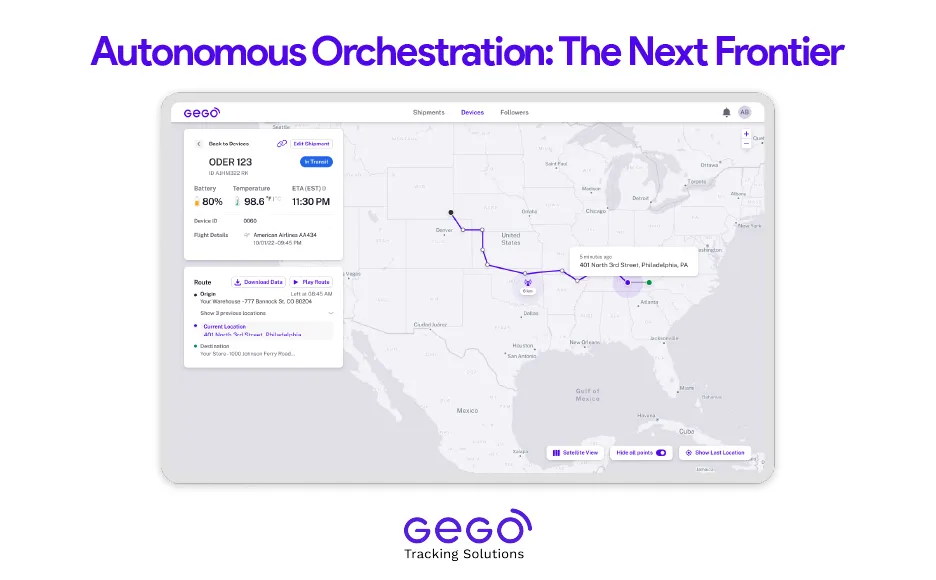

To mitigate these pressures, logistics providers are turning to real-time shipment monitoring solutions like GEGO Tracking Solutions.

Prevent Loss and Delay

With GPS tracking and geofencing, operators can monitor shipment progress across every handoff and carrier.

- Detect delays in transit

- Identify route deviations

- Respond quickly to hold-ups

Improve Cold Chain and Condition Visibility

For temperature-sensitive cargo, GEGO`s Temperature Beacon provides:

- Temperature, humidity, and shock monitoring

- Tamper alerts and motion detection

- Compliance with IATA and FDA guidelines

Streamline Exception Management

Real-time alerts help logistics managers:

- Escalate issues before cargo is compromised

- Document incidents with sensor data

- Improve performance reporting and service levels

Optimizing Holiday Operations with Supply Chain Intelligence

The most resilient logistics operations are built on data visibility and proactive control. With GEGO’s tracking platform, shippers can:

- Reduce WISMO calls (“Where Is My Order”)

- Improve coordination across 3PLs and carriers

- Capture shipment and exception data for auditing

- Enable smoother reverse logistics workflows

Conclusion: Holiday Season Visibility Is Non-Negotiable

With increased volume, cost, and complexity, holiday shipping isn’t just about speed—it’s about control.

Using GEGO’s real-time shipment tracking platform helps logistics providers and high-value cargo shippers stay ahead of seasonal risks, reduce claims, and deliver with confidence.