Why Cold Chain Compliance Matters in 2025

For healthcare and food industries, maintaining a robust cold chain isn’t just a best practice—it’s a critical necessity for public health and business continuity. For healthcare and food industries, cold chain compliance is the bedrock of product safety, public health, and business continuity. As we navigate 2025, regulatory scrutiny is intensifying, and the demand for absolute visibility and control over perishable shipments has never been higher.

Risks of non-compliance (health, financial, reputational)

Failing to adhere to cold chain regulations carries severe consequences. From a health perspective, temperature excursions can compromise the efficacy of vital medications, vaccines, and the safety of food products, leading to potential health crises. The financial repercussions are equally daunting, including significant product spoilage, costly recalls, regulatory fines, and legal liabilities. Beyond the tangible losses, the damage to a company’s reputation can be irreversible, eroding customer trust and competitive standing. It’s estimated that global cold chain failures contribute to approximately 20% of pharmaceutical product spoilage annually, costing the industry billions.

Key industries: healthcare & food logistics

The healthcare sector, encompassing pharmaceuticals, biotech, medical devices, and organ procurement organizations (OPOs), relies heavily on an unbroken cold chain to ensure product stability and patient safety. Vaccines, biologics, and specialized medications often have stringent temperature requirements, where even minor deviations can render them ineffective or harmful. UNOS Study Case

Similarly, the food logistics industry, including distributors of dairy, meat, frozen goods, and fresh produce, must maintain precise temperature controls from farm to fork. Breaches in the food cold chain can lead to bacterial growth, spoilage, and foodborne illnesses, directly impacting consumer health and safety.

Regulatory Overview

Navigating cold chain compliance requires understanding key frameworks that govern the handling of temperature-sensitive goods:

- FDA: Sets standards for the transport of drugs and food in the U.S.

- WHO: Provides global guidelines, particularly for vaccines and public health.

- EU GDP: Mandates strict distribution practices for medicinal products within the EU.

- HACCP: A preventive approach to food safety widely used for perishable goods.

Logistics managers must stay abreast of these evolving regulations, understanding their implications for operational procedures, technology adoption, and staff training. Proactive adherence not only mitigates risks but also builds a reputation for reliability and quality.

Checklist Categories

Achieving strong cold chain compliance requires a multi-faceted approach. Use this checklist to evaluate your current operations:

- Packaging & Insulation: Use validated thermal packaging that can maintain required temperatures for the full transit duration.

- Temperature Monitoring: Deploy calibrated temperature sensors (data loggers or real-time trackers) to capture accurate, continuous data.

- Real-Time Visibility: Use a solution that combines GPS with sensor data (temperature, humidity, etc.) for instant oversight.

- Geofencing & Alerts: Set up virtual boundaries and automated alerts to be notified of temperature excursions, route deviations, or unexpected delays.

- Documentation & Audit Trails: Maintain secure, digital records of all shipment data, including temperature logs and alert histories, for easy access during audits.

- SOPs & Training: Implement clear Standard Operating Procedures and ensure all staff are regularly trained on compliance protocols.

- Exception Handling: Have clear procedures in place to quickly respond to and mitigate any compliance breaches.

Role of Technology in Compliance

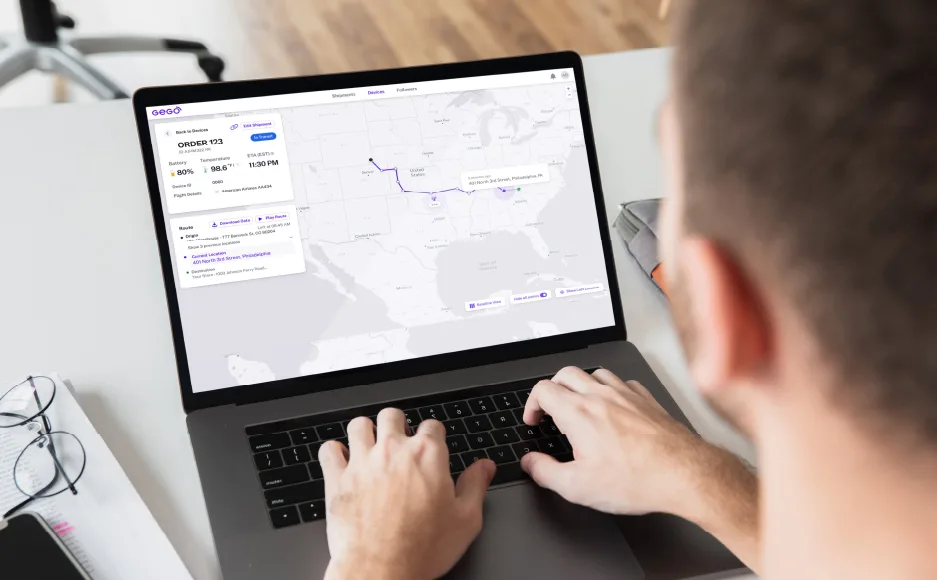

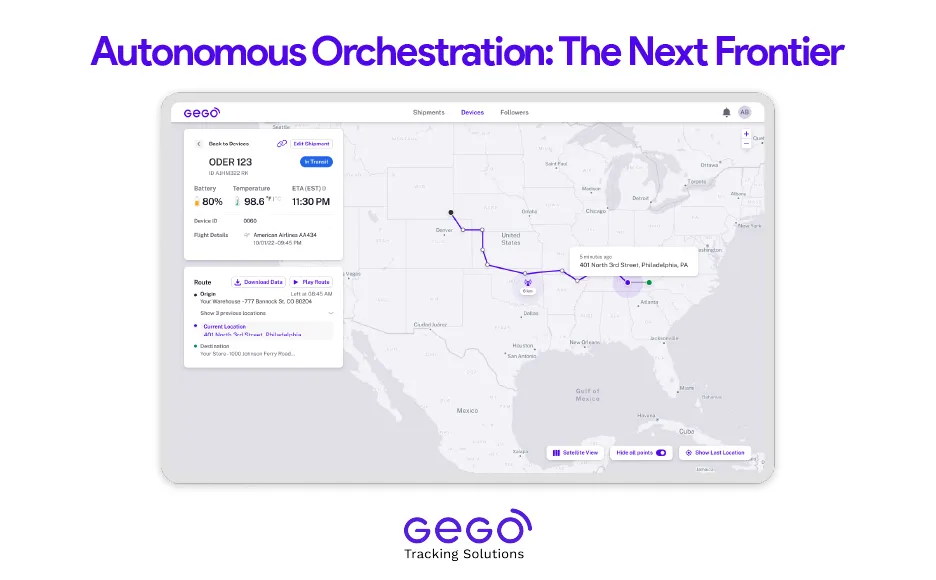

Modern technology, such as the GEGO shipment monitoring platform, is essential for a compliant cold chain. GEGO Tracking Solutions provides:

- Real-time Tracking: See your shipment’s exact location and condition at all times.

- Proactive Alerts: Receive instant notifications for any temperature deviations or other issues, allowing you to act before a product is compromised.

- Audit-Ready Reports: Automatically generate detailed reports with all the data needed to demonstrate compliance to regulators.

This technology helps prevent spoilage and penalties, building customer trust and providing a competitive advantage.

Outcomes & ROI of Strong Compliance

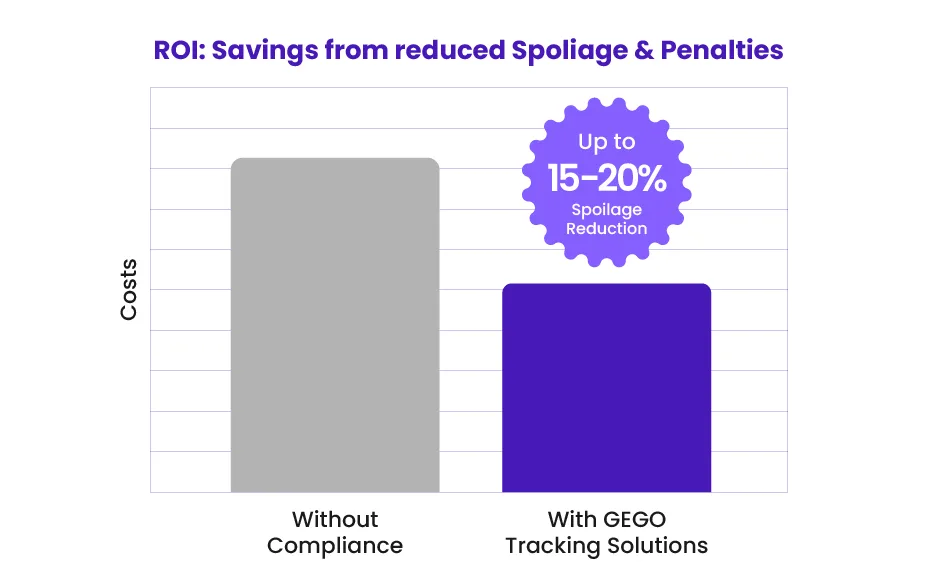

Investing in robust cold chain compliance through advanced tracking solutions like GEGO yields significant returns, extending far beyond simply avoiding penalties.

Reduced spoilage & penalties

By preventing temperature excursions and enabling rapid intervention, GEGO helps drastically reduce product spoilage. This directly translates to significant cost savings, especially for high-value pharmaceuticals or large volumes of perishable food. Furthermore, proactive compliance minimizes the risk of hefty fines and legal action from regulatory bodies, protecting your bottom line. According to industry reports, efficient cold chain management can reduce spoilage by up to 15-20% for certain products.

Improved customer trust & competitive advantage

Consistent adherence to cold chain standards builds an unshakeable reputation for reliability and quality. Customers in both healthcare and food industries demand transparency and assurance that their products are handled with the utmost care. Companies demonstrating superior cold chain tracking capabilities gain a distinct competitive advantage, fostering deeper customer trust and opening doors to new business opportunities.

In Conclusion

The demands of cold chain compliance are only growing in complexity, driven by evolving regulations and the increasing sensitivity of products. For healthcare and food logistics professionals, embracing cutting-edge technology is no longer optional, it’s essential for safeguarding public health, ensuring product integrity, and securing a competitive future.

By leveraging comprehensive solutions like GEGO’s real-time shipment monitoring platform, you can transform your cold chain from a potential liability into a source of strength and reliability. Proactive cold chain tracking and diligent adherence to compliance checklists are the keys to building a resilient, transparent, and trusted supply chain in 2025 and beyond.

Ready to enhance your cold chain compliance and gain unparalleled visibility?

Request a demo of GEGO’s shipment monitoring for cold chain compliance.

Or get started by downloading our Cold Chain Compliance checklist.

FAQ

What is cold chain compliance?

Cold chain compliance refers to adhering to strict regulatory requirements and industry best practices for maintaining specific temperature ranges for sensitive products (like pharmaceuticals, vaccines, and perishable foods) throughout their entire supply chain, from manufacturing to final delivery.

What are the key requirements in a cold chain?

Key requirements include validated thermal packaging, calibrated temperature monitoring devices, real-time visibility, robust Standard Operating Procedures (SOPs), comprehensive documentation, and thoroughly trained staff.

How do you monitor temperature during transit?

Temperature during transit is monitored using specialized devices such as data loggers and real-time GPS trackers with integrated temperature sensors. These devices continuously record and, in the case of real-time trackers, transmit temperature data to a central platform, allowing for constant oversight and immediate alerts.

What technologies support cold chain compliance?

Technologies supporting cold chain compliance include IoT-enabled real-time GPS and multi-sensor tracking devices, cloud-based monitoring platforms with analytics and reporting capabilities, geofencing, automated alert systems, and digital audit trails.

What happens if cold chain compliance is breached?

Breaches in cold chain compliance can lead to product spoilage, loss of product efficacy (e.g., vaccines), public health risks (e.g., foodborne illnesses), costly product recalls, significant regulatory fines, legal liabilities, and severe damage to a company’s reputation and customer trust.